Axial flow pumps, also known as elbow or propeller pumps, are used in high flow and low head applications. JEC offers a complete range of low and high pressure, horizontal and vertical axial flow pumps especially designed to handle severe pumping conditions.

The basic operating principle of a pump is that it uses energy to move fluids from one point to another. All pumps contain a moving component. The moving component (impeller, vane, piston) displaces air, decreasing the pressure and creating a partial vacuum. Air or fluid then moves into this area of low pressure.

Helps in dewatering These pumps can lifts water from rivers, canals or streams and can be used for dewatering purposes be it for a ship or an industry. Sewage Treatment The propeller pumps also come in handy for sewage treatment, be it in a private, municipal or industrial set-up

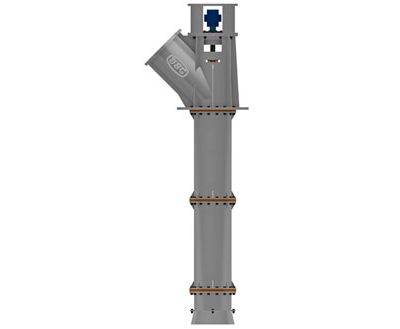

Axial flow pumps are one of three subtypes of centrifugal pumps, the others being mixed flow and radial flow. Of these three types, axial flow pumps are characterized by the highest flow rates and lowest discharge pressures. They direct flow in a straight line parallel to the impeller shaft rather than radially (perpendicular to the shaft). The impeller is shaped like a propeller and contains only a few (typically three or four) vanes. The impeller is driven by a motor that is either sealed directly in the pump body or by a drive shaft that enters the pump tube from the side. The impeller looks and operates similar to a boat propeller, which is the reason why axial flow pumps are also called propeller pumps.